1. Features

Good high-temperature resistance, low-temperature resistance (polypropylene can be used for a long time at 150℃ and polyester can be used for a long time at 260℃), aging resistance, ultraviolet resistance, high elongation, good stability and air permeability, corrosion resistance, sound insulation, moth prevention and non-toxicity.

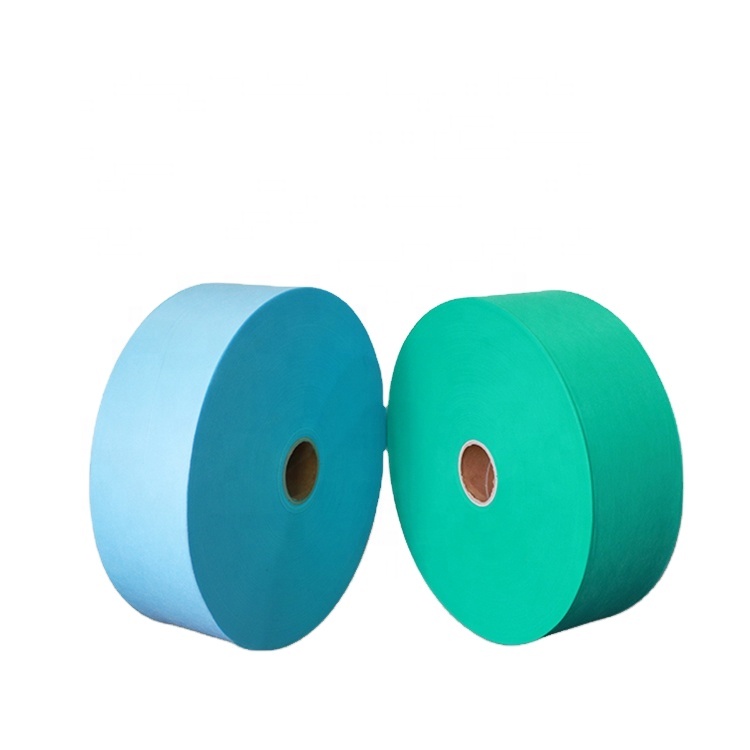

Two: The main materials of spunbonded non-woven fabrics are polyester and polypropylene.

The main products of spunbonded non-woven fabrics are polypropylene and polyester (long fiber and short fiber) non-woven fabrics. The most common and commonly used applications are non-woven bags, non-woven packaging, etc. It’s easy to identify spunbonded nonwovens, and generally the two-way fastness is good. Generally, the rolling point of spunbonded nonwovens is rhombic.

On the application level, it can also be used as flower packing cloth, luggage cloth, etc., and its characteristics of wear resistance, firm hand feeling and so on make it the best choice for making such products.

Third, the technological process of spunbonded non-woven fabrics

Polypropylene: polymer (polypropylene+recycled material)-high temperature melt extrusion with large screw-filter-metering pump (quantitative delivery)-spinning (up and down stretching and suction at spinning inlet)-cooling-airflow traction-net curtain forming-up and down pressing rollers (pre-reinforcement)-hot rolling (reinforcement) with a rolling mill-winding-reverse cloth cutting.

wirte:Eric Wang

Post time: Aug-26-2022