Spunbond non-woven fabric, also known as polypropylene spunbond non-woven fabric, polypropylene spunbond non-woven fabric, is a new generation of environmentally friendly materials, with water repellent, breathable, flexible, non-combustible, non-toxic and non-irritating, rich in colors .

If the material is placed outdoors and decomposed naturally, its longest life is only 90 days, and it will decompose within 8 years when placed indoors.

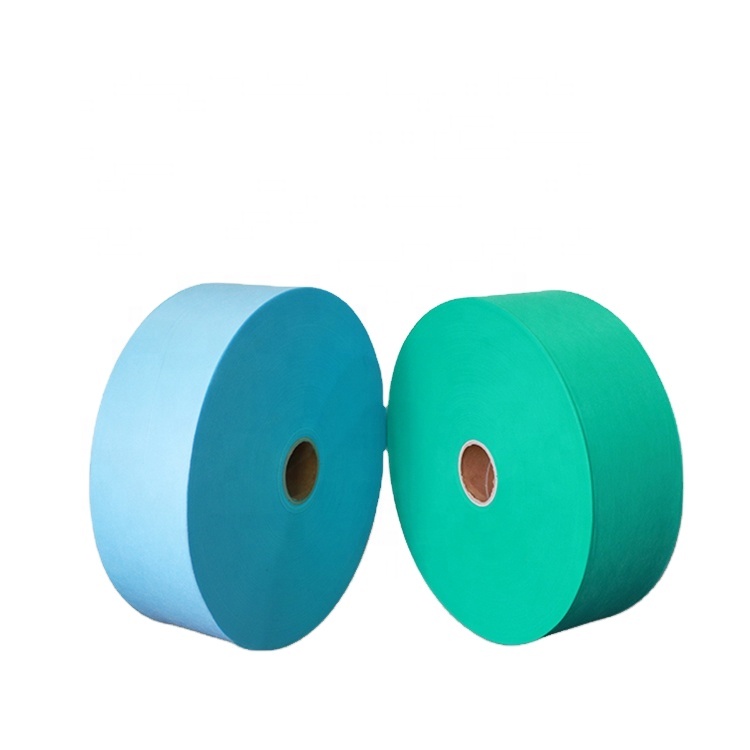

PP spunbond non-woven fabric is a kind of non-woven fabric, which is made of pp polypropylene as raw material, polymerized into a network by high temperature drawing, and then bonded into a cloth by hot rolling.

Because the technological process is simple, the output is large, and it is non-toxic and harmless to the human body. Therefore, it is widely used in various fields such as non-woven fabrics for medical and sanitary materials, non-woven fabrics for agriculture, non-woven fabrics for industrial use, and non-woven fabrics for packaging materials.

1. Polypropylene material

Polypropylene is a kind of polymer commonly used in the spinning process, and the main performance parameters are isotacticity, melt index (MFI) and ash content.

The spinning process requires the isotacticity of polypropylene to be above 95%, and if it is less than 90%, spinning is difficult.

During the polymerization process, three configurations of polymers can be produced due to the different positions of the methyl groups in the steric space.

Material: 100% polypropylene fiber

Processing method: spunbond method

Color: Normally according to the color card provided by the factory, or special colors can be made according to customer requirements (Pantone card can be made)

Texture: small hole dots/sesame dots/cross pattern/special pattern (most of them are small hole dot patterns on the market, sesame dots are mostly used for sanitary materials, cross grains are used for shoe materials and packaging, and there are fewer one-line patterns.)

Features: It is a new generation of environmentally friendly materials, with moisture-proof, breathable, flexible, light weight, non-combustible, easy to decompose, non-toxic and non-irritating, recyclable, soluble, waterproof, dust-proof, UV-proof, rich in color, price Inexpensive and recyclable.

2. Purpose

Spunbond non-woven fabrics are mainly used in medical hygiene materials, agricultural coverings, home textiles and household products, packaging materials, shopping bags, etc. New products emerge in an endless stream and are widely used.

Such as masks, medical disposable isolation gowns, head covers, shoe covers, diapers, adult urinary incontinence and hygiene products, etc.

17~100gsm (3% UV) for agricultural coverage

15~85gsm for home textile lining

40~120gsm for household items

50~120gsm for packing material

100~150gsm is used for shutters, car interiors, photography background cloth, advertising cloth, etc.

Recommend excellent PP spunbond non-woven fabric manufacturers for you:

https://www.ppnonwovens.com/dot-product/

By Jacky Chen

Post time: Aug-04-2022